Circularity: the model for a sustainable future

November 2021, by Alan Grant

November 2021, by Alan Grant

OPINION PIECE

It is now understood that widespread and immediate action is required to limit climate change and the impacts of human activities on the environment. Here, Alan Grant our Design and Development Director discusses the importance of applying circular economy principles and how the design, manufacture and management of urban lighting can contribute to this goal.

Minimising climate change and improving the sustainability of our activities is essential. In 2019, the UK Government committed to lowering the country’s greenhouse gas emissions to net zero by 2050. However, earlier this year the Climate Change Committee (CCC) warned that the UK is experiencing major climate changes and at a rate that the country cannot keep pace with – underling the urgency of taking action.

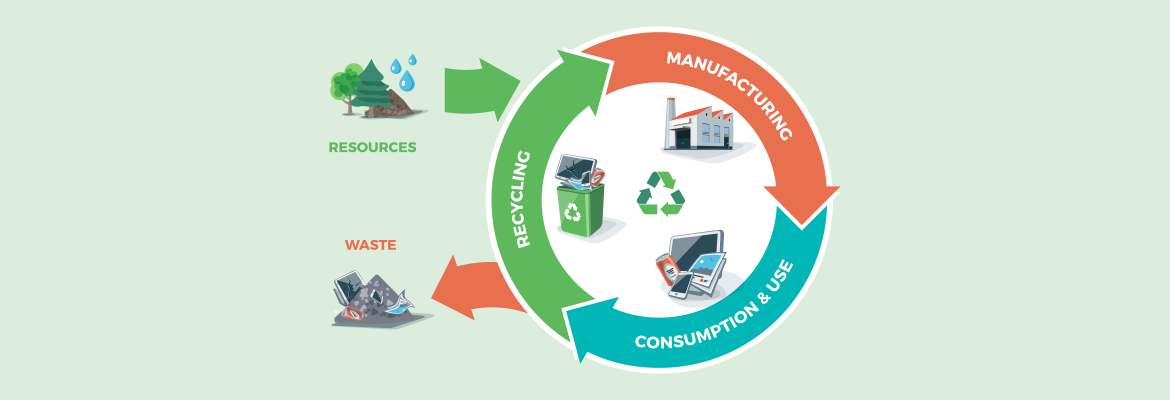

The traditional linear ‘make, use, dispose’ model of consumption is not only extremely wasteful but contributes to greenhouse gas emissions. Extracting, refining and transporting raw materials, often across large distances, to manufacture new products has a significant carbon impact. Creating a circular economy helps minimise both the level of waste and environmental impact.

Environmental action organisation WRAP states that the aim of a circular economy is to: “Keep resources in use for as long as possible, extract the maximum value from them while in use, then recover and regenerate products and materials at the end of each service life.”

|

|

|

Alan Grant, Design & Development Director With extensive industry experience spanning over 30 years, Alan has a unique ability to translate technical complexities, such as the effects of colour temperature and light quality on human physiology. As Design and Development Director at DW Windsor, Alan is responsible for the creation of new products and for bringing new technical innovations to market. |

Circularity in lighting

Within the lighting industry, the concept of circularity has recently gained increased attention with the development of CIBSE Technical Memorandum 66 (TM66), published by the Society of Light and Lighting (SLL). TM66 will provide guidance on introducing circular economy principles across the sector and importantly includes two Circular Economy Assessment Methods. CEAM Make and CEAM Specify, provide a clear star rating system to give manufacturers and designers specific and useable metrics to evaluate and measure products, ultimately helping them to drive improvements.

Much of the general discussion on circularity has been focused on the end of a product’s lifecycle through the recovery and recycling of its materials. However, ‘keeping resources in use for as long as possible’ by designing with longevity in mind also has a key role to play. This means creating products that will last, can be upgraded as technology advances and be serviced and repaired easily.

Lighting is an area where there is significant scope to achieve this. The nature of LED lighting means that it has an extremely long service life, with up to 100,000 hours for some external LED products. If an average of 12 hours use per day is assumed, this lifespan equates to more than 20 years.

The circular economy in the design and lighting industry cannot rely on recycling alone – there must also be conscious efforts to reduce, reuse and maintain. Ideally, products should be easily repaired, or easily retrieved and reused. As specifiers, we have the opportunity to ensure that we factor these elements into our decision making.

The limiting factor for the lifespan of lighting products is often advances in technology that make older units obsolete. This is why products must also be designed to allow simple upgrades as innovations are made. For example, products that are designed with interchangeable light engines allow customers to benefit from the latest in energy efficient LED technology without the cost and waste of replacing the whole luminaire. Also, budgetary restrictions and competing priorities mean that some customers may not be in a position to invest in the latest technologies. However, products designed to be, for example, Smart City ready mean that upgrades can be made at a later date without extensive replacements.

Another key factor in ensuring a long service life is designing the products to be easy to service, repair and refurbish. For example, it is better to have products assembled using removeable fixings, such as bolts and screws, instead of using adhesives or rivets that make repairs more challenging.

Finally, it is also essential to ensure that the design of the luminaire and materials used allow the product to be recycled when it does eventually come to the end of its life. Some materials are simpler to reclaim and reuse. For example, aluminium is an abundant resource which can be endlessly recycled with no loss in quality. This makes it ideal for creating a circular economy. Also, recycling reclaimed aluminium requires up to 95% less energy compared with primary aluminium production, meaning a significant reduction in carbon emissions.

DW Windsor products are tested to the highest standards to ensure product longevity

The designer’s view

To really make a difference, this circular approach needs to be integrated across all parts of the supply chain – meaning manufacturers and lighting specifiers alike must place this way of thinking at the heart of everything they do.

Renowned lighting designer and founding member of the Green Light Alliance, Sophie O’Rourke, commented: "The circular economy in the design and lighting industry cannot rely on recycling alone – there must also be conscious efforts to reduce, reuse and maintain. We, as specifiers, need to ensure that we are factoring these elements into our scheme designs as much as manufacturers are factoring them into their product designs. We need to be asking ourselves if we can perhaps reduce the quantity of fittings used on a project, or if the products in question are long-lasting enough for the potential extent of the project and onwards. Ideally, products should be easily repaired, or easily retrieved and reused. As specifiers, we have the opportunity to ensure that we factor these elements into our decision making.

“The release of TM66 gives us a new tool in our toolbox that allows us to compare fittings in order to make these decisions. Whereas before, we may have been looking to characteristics such as efficacies, CRIs and lamp life to make a decision, we can now also factor in the circular economy for a more well-rounded outcome."

Daytona has been designed with easily replaceable light engines, allowing for future upgrades

Developing new solutions

DW Windsor has long subscribed to a circular design philosophy, ensuring our products are built to last and easy to upgrade and maintain. We have invested heavily in research and development, as well as industry leading in-house testing facilities, to ensure that our products have the required durability and perform as intended whilst also taking advantage of the latest LED technologies.

Our new street lighting solution, Daytona, has been designed with circularity in mind. It features fully upgradable LED light modules that can be retrofitted quickly and easily, helping to extend the luminaire’s service life. The luminaire also features quick-release latches for toolless entry, simplifying the installation and maintenance process.

Daytona is also Smart City ready and can be specified with a selection of internal nodes plus both NEMA and Zhaga sockets to accommodate a range of external sensors and networking solutions, providing added functionality, now or in the future.

For long-term durability and improved recyclability, Daytona is manufactured from high-pressure die-cast LM6 corrosion-resistant aluminium. The luminaire has also been designed with mechanical fixings for easy disassembly at the end of its lifespan.

Click here to find out more about Daytona.